Why Can’t You Answer These 5 Questions About Your Own Facility?

Think you’re running a tight operation? Here’s a quick test. Answer these five questions about your leisure facility right now:

How many procedures do you have? Who’s read them? On average, how many tasks per week does it take to run your business? What’s outstanding right now as we speak? When will you know the answers to these questions?

If you hesitated on even one, you’re managing without operational intelligence. This isn’t about compliance—it’s about whether you’re running your facility or just reacting to it.

The difference matters when insurance auditors ask for evidence, when your area manager questions capacity, when incidents require proof of training, or when you’re trying to work out why your team feels overwhelmed. Let’s break down why these questions are impossible to answer with traditional systems—and what that blind spot is costing you.

Question 1: How Many Procedures Do You Have?

Take a guess. Fifty? A hundred and fifty? Three hundred?

Most leisure managers dramatically underestimate because documents are scattered everywhere. Shared drives. Team folders. Inboxes. Printed copies in site offices. You’ve got opening procedures, closing procedures, incident procedures, emergency procedures, equipment procedures, customer service procedures—hundreds more that govern daily operations.

When your insurance auditor asks, “Can I see your procedure for X?” you need to know it exists, where it lives, and that it’s the current version. When new legislation drops (remember the COVID scramble?), you need to know which procedures require updates. When staff say “I didn’t know we had a procedure for that,” you need to close that gap.

The traditional approach: Procedures live in Word documents on a shared drive. Someone created a folder structure that made sense years ago. New procedures get added wherever seems logical. Duplicate versions exist. Nobody knows the total count. The procedure register was last updated eighteen months ago.

The consequence: You can’t demonstrate systematic operational management to insurance companies. Staff work from outdated procedures. You waste time during audits trying to compile a master list. You duplicate effort creating procedures that already exist somewhere.

Question 2: Who Has Read Them?

Even harder. You’ve got fifty-plus staff across multiple shifts and roles. Permanent staff, casual staff, agency cover, contractors. You rolled out updated safeguarding procedures last month. Who’s actually read them?

When incidents occur, “we issued the procedure” isn’t enough. Your insurance company needs proof of acknowledgement. HSE inspectors want evidence staff were working to documented procedures. Quest assessors examine whether staff are trained and competent for their roles.

The traditional approach: Procedures get sent via email. Staff are expected to read them and confirm via reply. Or you print them, staff sign a sheet, and the sheet goes in a file. Or you discuss them in team meetings and hope everyone who needs to know was present. Tracking who’s read what becomes impossible at scale.

The consequence: Staff operate without current information. You can’t demonstrate competency to auditors. When incidents occur, you can’t prove staff were informed. Assessment preparation becomes a paper chase trying to reconstruct who knew what when. Insurance premiums increase because you lack evidence of systematic training.

Question 3: On Average, How Many Tasks Per Week Does It Take to Run Your Business?

This might sound like a strange question, but it’s fundamental to understanding operational capacity and workload. Is it two hundred tasks per week? Five hundred? A thousand? Do you know if that’s increasing, stable, or decreasing? Do you know which tasks consume the most time?

When your centre manager says “the team is overwhelmed,” you need data to understand if workload has genuinely increased or if task completion has decreased. When budgets are under pressure, you need to demonstrate operational efficiency and identify where time is being spent.

The traditional approach: Tasks live in email threads, handover notes, WhatsApp groups, verbal instructions, and individual to-do lists. Weekly task counts are unknowable because there’s no centralised view. The plant room checks might be on a clipboard. The deep cleans are in someone’s diary. The equipment maintenance is tracked by whoever remembers to do it.

The consequence: You can’t demonstrate proactive facility management to assessors. You can’t identify efficiency improvements. You can’t forecast staffing requirements accurately. You can’t defend your team when leadership questions capacity. Tasks fall through gaps because nobody’s tracking the total volume.

Glasgow University managers were spending two hours weekly chasing task completion and preparing for operational meetings. After implementing digital task visibility, that dropped to ten minutes per week. The time saved went straight into service improvement and staff development.

Question 4: What’s Outstanding Right Now as We Speak?

Right this second, which tasks are overdue? Which risk assessments need review? Which training certificates are about to expire? Which problems are logged but unresolved? Which equipment maintenance is coming due?

Insurance auditors don’t assess your operation in theory—they assess what’s actually happening. If pool testing is overdue when they arrive, you’ve got a problem. If your duty manager can’t demonstrate real-time accountability, you’ve got a problem. If problems are logged but not resolved systematically, you’ve got a problem. Your operational dashboard needs to show current reality, not last week’s spreadsheet update.

The traditional approach: Outstanding work lives in people’s heads, email inboxes, handover sheets, and task lists scattered across devices and notebooks. Your duty manager might know their section’s outstanding work, but they can’t see across sites or departments. You find out things are overdue when someone asks “Did that get done?” or when something goes wrong.

The consequence: Tasks slip. Standards drop. Insurance auditors question your systems. HSE inspectors find gaps. Problems escalate because nobody knew they were outstanding. Your team works reactively because they can’t see what’s coming. You can’t demonstrate operational control when it matters most.

Question 5: When Will You Know the Answer to These Questions?

This is the question that cuts through. If you can’t answer questions one through four right now, when will you be able to? Tomorrow? Next week? When your insurance audit happens? When your area manager asks why standards are slipping? When an incident requires evidence you don’t have?

Operational excellence isn’t something you achieve once—it’s a state you maintain continuously. If your operational intelligence requires days of manual data gathering, you’re not operationally excellent. You’re performing last-minute evidence theatre.

The traditional approach: You gather answers when forced to. Audit preparation becomes a multi-week project where staff compile evidence instead of managing facilities. Service standards decline during preparation because attention shifts from customers to auditors. You achieve short-term compliance, then operational visibility fades until the next assessment cycle.

The consequence: You manage reactively. You can’t demonstrate sustained operational excellence. You waste time and resources on periodic evidence gathering. Most critically: you never actually know the answers to the five questions that determine whether you’re running your facility or just reacting to it.

The Real Cost of Operational Blind Spots

Here’s what these blind spots cost beyond the obvious compliance risks:

Management time: Hours spent gathering information that should be instantly available, preventing strategic thinking and proactive improvement.

Insurance exposure: Inability to prove staff training, procedure acknowledgement, or systematic competency management when incidents occur or audits happen.

Staff frustration: Teams working without clear visibility on priorities, completion status, or acknowledgement of effort.

Service standards: Operational attention diverted to evidence gathering rather than customer experience and facility excellence.

Strategic decisions: Leadership making decisions based on gut feel and anecdotal evidence rather than operational data.

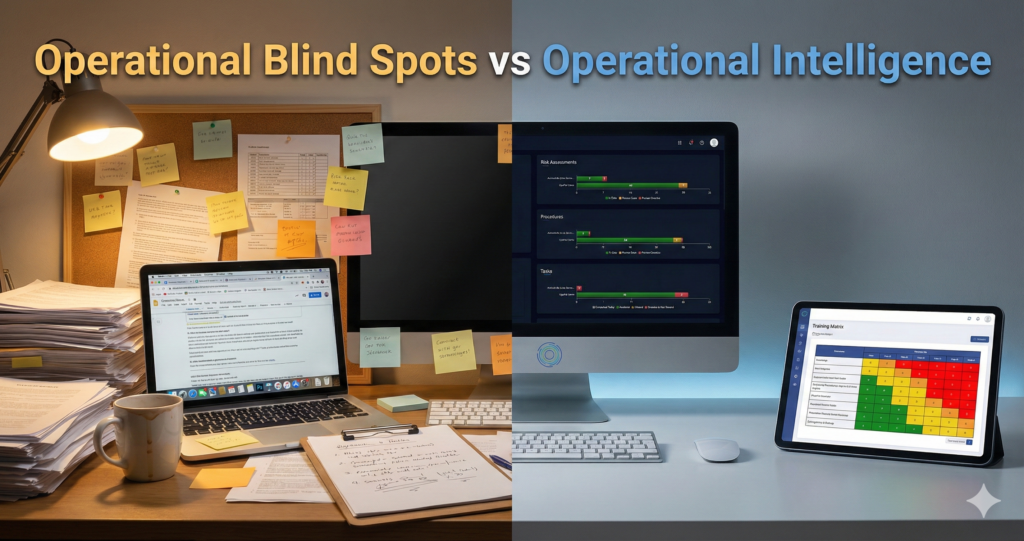

From Operational Blind Spots to Operational Intelligence

Digital operations platforms transform these unanswerable questions into dashboard reality. Instead of spreadsheets and shared drives, you get live visibility into every aspect of your operation.

Procedure counts become instantly visible, broken down by category, site, and department. Version control ensures everyone works from current information. When you update a procedure, you can see exactly who’s acknowledged the changes and who hasn’t—no email chains, no missing sign-off sheets.

Training status moves from expired certificates discovered too late to ninety-day advance warnings with complete visibility across individual, site, and organisation levels. When your insurance auditor asks about lifeguard qualifications, you pull up the training matrix in seconds.

Task volume shifts from unknown to analysed. Week-by-week completion rates. Average completion time. Workload trends that inform capacity planning and efficiency improvements. When your area manager questions whether you need additional staff, you show them the data.

Outstanding work becomes visible in real-time. Overdue tasks automatically sort to the top. Pending reviews, expiring qualifications, and unresolved problems display across your entire operation. Your duty manager can demonstrate accountability instantly, not just during audits.

Systems like OpsPal provide this operational visibility through live dashboards accessible on any device. The answers to all five questions become available instantly, twenty-four-seven, without manual data gathering or staff interruption.

This isn’t about replacing human judgement with software. It’s about giving leisure managers the operational intelligence they need to make informed decisions, demonstrate excellence to auditors, and focus attention on service delivery rather than evidence compilation.

When Will You Stop Guessing?

The five questions at the start of this article aren’t gotchas—they’re diagnostics. If you can answer them instantly, you have operational intelligence. If you need hours or days to gather the answers, you have operational blind spots.

Most leisure managers know they need better operational visibility. They just keep putting it off until “after peak season” or “when we’ve got time to implement properly” or “when the budget allows.”

Meanwhile, the five questions remain unanswerable. Tasks slip. Standards drop. Evidence gathering becomes a crisis. Insurance auditors raise concerns. Assessment preparation disrupts operations.

The managers who answer these five questions instantly aren’t smarter or less busy—they just stopped accepting operational blind spots as normal.

When will you?